Microchannel coils represent a significant advancement in thermal management technologies, particularly in applications where space and efficiency are at a premium. These compact devices utilize small channels to enhance the heat transfer process, making them highly effective in various systems, from HVAC units to automotive cooling systems.

Key Points:

- Microchannel coils enhance heat transfer efficiency due to their compact and optimized design.

- They consist of multiple small-diameter parallel channels, increasing surface area for better heat exchange.

- Aluminum and copper are the most common materials used, ensuring durability and corrosion resistance.

- Higher heat transfer coefficients make microchannel coils superior to traditional designs.

- They are widely used in HVAC systems, automotive cooling, and industrial thermal management.

- Ongoing research is leading to improved manufacturing techniques and adaptive cooling technologies.

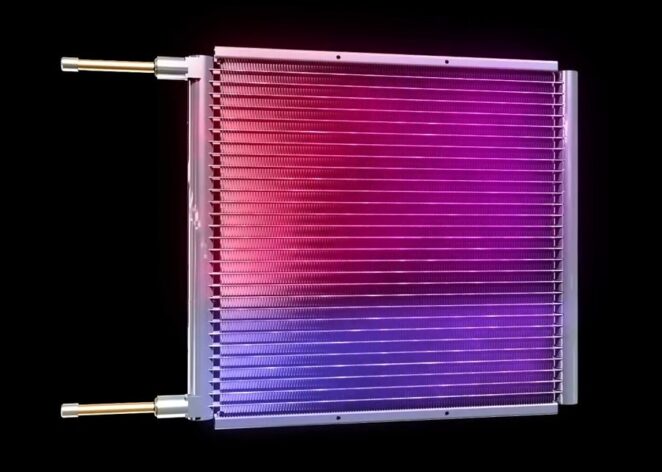

Design and Structure

The unique design of microchannel coils sets them apart from traditional heat exchanger technologies. These coils are made up of numerous parallel channels, which are typically less than 1 mm in diameter. This small-scale design allows for a larger surface area relative to the volume, improving the thermal performance significantly like Kaltra.

Material Choices

The choice of materials for microchannel coils influences their thermal conductivity and overall efficiency. Common materials include aluminum and copper, both known for their excellent heat transfer properties. Aluminum, in particular, is favored due to its lightweight nature and resistance to corrosion, making it suitable for prolonged use in varying environmental conditions.

Thermal Performance Metrics

Evaluating thermal performance involves several key metrics, each providing insights into how effectively a microchannel coil can dissipate or absorb heat.

Heat Transfer Coefficient

The heat transfer coefficient is a crucial parameter that reflects the efficiency of heat exchange within the coil. Microchannel coils exhibit higher heat transfer coefficients compared to traditional coils due to their design, which promotes turbulent flow and increases contact area.

Effectiveness

Effectiveness measures the coil’s ability to transfer heat between two fluids. High effectiveness in microchannel coils is achieved through optimized flow arrangements and channel geometries, ensuring minimal thermal resistance.

Application Scenarios

The applications of microchannel coils span various industries, each benefiting from enhanced thermal management.

HVAC Systems

In heating, ventilation, and air conditioning systems, microchannel coils are utilized for their compact size and efficiency. By reducing refrigerant charge and enhancing heat transfer, they contribute to energy savings and improved system performance.

Automotive Cooling

Microchannel coils are increasingly adopted in automotive applications, such as radiators and intercoolers. Their ability to maintain optimal engine temperatures while minimizing weight directly impacts vehicle performance and fuel efficiency.

Industrial Applications of Microchannel Coils

Microchannel coils are also making an impact in industrial cooling systems where high thermal loads require efficient dissipation.

- Power Plants: Used in heat exchangers to maintain efficiency in steam cycles.

- Electronics Cooling: Helps regulate the temperature of high-performance computing systems and data centers.

- Chemical Processing: Utilized in reactors where precise temperature control is necessary.

- Aerospace Industry: Applied in aircraft thermal management to maintain optimal operating conditions.

Future Developments

Research in microchannel technology continues to evolve, focusing on enhancing performance and expanding applications. Innovations in manufacturing techniques, such as additive manufacturing, allow for more complex designs that can further optimize thermal performance. Additionally, integrating smart technologies into microchannel systems could lead to adaptive cooling solutions that respond dynamically to changing conditions.

As industries look for ways to improve energy efficiency and reduce carbon footprints, the role of microchannel coils is likely to grow. Their potential for superior thermal management makes them an exciting area for ongoing research and development.

The advancements in this field highlight the importance of understanding and harnessing the properties of microchannel coils, such as those offered by microchannel coil technologies, to maximize efficiency in various applications.

Advantages of Microchannel Coils Over Traditional Systems

Microchannel coils offer significant benefits over conventional heat exchanger designs.

- Higher Efficiency: Increased surface area leads to better heat transfer rates.

- Compact Size: Their small form factor allows for better integration into modern systems.

- Lower Refrigerant Charge: Reduces the environmental impact and operating costs.

- Durability: Aluminum construction provides resistance to corrosion and extended service life.

- Weight Reduction: Lighter materials make microchannel coils ideal for weight-sensitive applications, such as aerospace and automotive industries.

Challenges in Implementing Microchannel Technology

While microchannel coils offer numerous advantages, their implementation also presents challenges.

- Manufacturing Complexity: Requires advanced fabrication techniques.

- Higher Initial Costs: More expensive than traditional heat exchangers due to specialized production methods.

- Maintenance Considerations: Smaller channels are prone to clogging if contaminants are present in the system.

- Integration Challenges: Existing systems may require modifications to fully utilize microchannel coil technology.

Optimizing Performance in Microchannel Systems

To maximize efficiency and longevity, proper maintenance and system design considerations are crucial.

- Regular Cleaning: Prevents clogging and maintains optimal heat transfer.

- Correct Refrigerant Selection: Using the right fluid ensures better compatibility and efficiency.

- Proper Installation: Ensures that coils function at peak performance without leaks or structural issues.

The Role of Computational Simulations in Microchannel Coil Design

Computational simulations play an essential role in optimizing microchannel coil performance.

- Thermal Analysis: Simulates heat dissipation efficiency before physical production.

- Fluid Dynamics Modeling: Helps in designing channel geometries that maximize heat transfer.

- Material Testing: Evaluates the longevity and durability of different coil compositions.

- Predictive Maintenance: AI-powered simulations can forecast wear and optimize maintenance schedules for long-term reliability.

An Overall Perspective

The introduction of microchannel coils represents a paradigm shift in thermal performance enhancement. Their compact design, efficiency, and suitability for diverse applications position them as critical components in modern engineering solutions. As technology progresses, the understanding and implementation of these coils will undoubtedly continue to evolve, offering new opportunities for innovation in thermal management strategies.

The potential for integrating AI-driven optimization and further miniaturization suggests that the future of thermal management will rely heavily on advancements in microchannel technology. Expanding applications in aerospace, medical cooling, and renewable energy systems further highlight the growing importance of these coils in modern engineering. As industries push towards sustainability, microchannel coils stand at the forefront of energy-efficient cooling solutions, driving the next generation of thermal management innovations.