Label printing is an indispensable facet of modern branding and marketing, acting as a visual conduit that seamlessly connects consumers to a brand’s ethos and values. In a marketplace teeming with choices, high-quality labels are instrumental in shaping consumer perceptions, enabling products to distinctly stand out and secure a formidable presence.

The significance of labels transcends aesthetic appeal; it’s about creating memorable interactions and fostering enduring relationships with the consumers. This guide aims to enhance your comprehension of label printing by delving deeply into its multifaceted aspects.

It provides a comprehensive overview of printing technologies, materials, design principles, and the evolving trends of 2024, ensuring your labels resonate profoundly and leave a lasting impression.

Understanding Label Printing Technologies

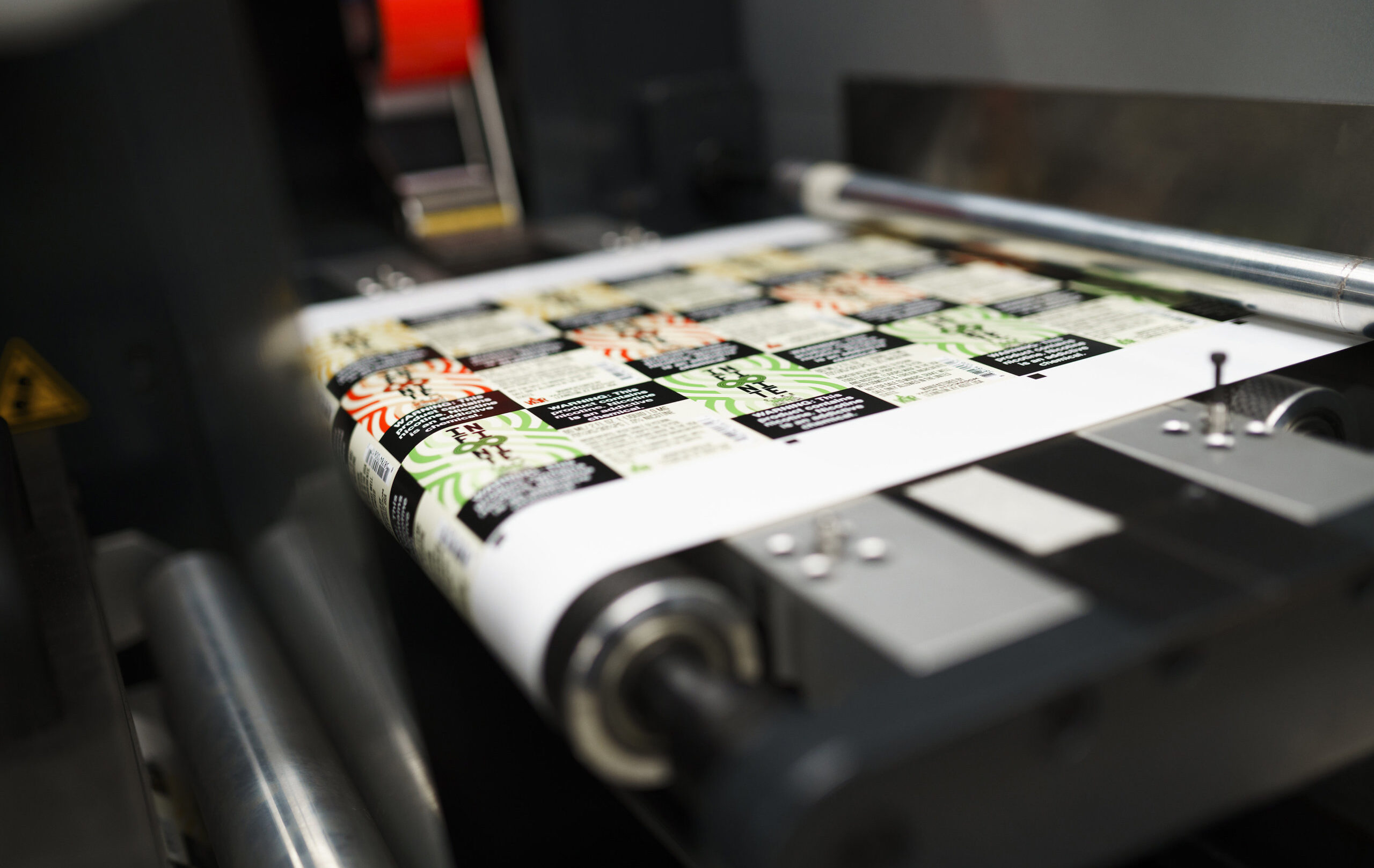

The year 2024 ushers in a diverse array of label printing technologies, each offering unique capabilities and advantages. Among the myriad of options available, digital, flexographic, and offset printing methods are predominantly utilized.

Digital printing stands out for its exceptional versatility and swift turnaround times, making it an ideal choice for projects with intricate designs and shorter runs. It is especially advantageous when customization and adaptability are of paramount importance.

On the other hand, a flexographic label printer, leveraging its flexible relief plates, is unparalleled for high-volume productions, offering meticulous precision and consistent high speed. It excels in producing high-quality labels at an economical cost for large-scale projects.

In contrast, offset printing operates through a meticulously structured plate and rubber blanket mechanism and is renowned for delivering unmatched quality and detail, especially for extensive print jobs. It’s crucial to meticulously assess the specific needs, budget constraints, and scale of your printing project to select the most suitable technology.

Choosing the Right Label Materials

Choosing the appropriate material is an integral step in the label printing process, affecting both the aesthetic appeal and durability of the label.

Different materials such as paper, vinyl, and foil are typically used, each offering unique characteristics and applicabilities. Paper labels, known for their versatility and cost-effectiveness, are a popular choice for products that don’t require exposure to moisture or drastic temperature changes.

Vinyl labels, resilient and waterproof, are suitable for products exposed to varying environmental conditions, ensuring longevity. Foil labels, adding a premium and luxurious finish, are often used to elevate the product’s visual appeal.

Understanding the product type, application, and the conditions it will be subjected to is crucial in selecting the most suitable material that aligns with the brand’s vision while ensuring durability and aesthetic coherence.

Designing Eye-Catching Labels

Crafting a label that catches the eye and remains memorable requires a blend of design principles, creativity, and an understanding of the product’s essence. It’s essential to fuse color theory, typography, and imagery harmoniously to convey the brand’s message effectively and create a lasting impression.

Color, being a powerful communication tool, needs to be selected meticulously, reflecting the brand’s personality and resonating with the target audience. Typography, the art of arranging text, should be legible and complementary to the overall design, enhancing the label’s message and aesthetic.

Label Printing Software and Tools

Navigating the realm of label printing requires familiarizing oneself with an array of software and tools designed for creating impeccable labels.

Understanding the nuances of popular label design software is imperative to sculpt labels that are both visually engaging and convey the brand essence succinctly. It is also crucial to be adept at incorporating elements like barcodes and QR codes, integral for functionality and user interaction.

Preparing Artwork for Printing

To achieve a flawless print, attention to detail in preparing artwork is indispensable. Embracing guidelines regarding file formats, resolution, and color modes is crucial to prevent discrepancies in the final print.

The pre-press process and proofing are essential stages, ensuring the artwork is refined and aligned with printing specifications. It is about striking a balance between design aspirations and printing realities, aligning creative visions with technical constraints to render labels that are true to the conceived design.

Customization and Variable Data Printing

Customization is the linchpin of contemporary label printing, allowing brands to resonate on a personal level with consumers.

Employing Variable Data Printing (VDP) allows for the creation of personalized labels, enhancing consumer engagement. Industries, where personalization is key, benefit immensely from VDP, making every interaction unique and more memorable. It’s about leveraging personalization to add a layer of exclusivity and individual acknowledgment to every product.

Label Printing Techniques

Advanced techniques like embossing, debossing, and foiling are intricate methods used to instill elegance and uniqueness in labels. These techniques are not just about aesthetic embellishments; they are about adding tactile dimensions to labels, making them a multi-sensorial experience.

Integrating these sophisticated techniques requires a meticulous approach to design and printing, ensuring every detail is accentuated to elevate the overall appeal of the product.

Quality Control and Inspection

Quality control is a cornerstone in label printing, essential for maintaining consistency and accuracy in every print. Inspection methods vary, but their essence lies in identifying and rectifying inconsistencies, ensuring every label reflects the brand’s standard of excellence.

Addressing common issues proactively is pivotal in maintaining the integrity of the label, making it a true representation of the brand’s commitment to quality.

Label Printing for Various Industries

The nuances of label printing diverge across industries like food, cosmetics, and pharmaceuticals, each having distinct regulations and requirements. Comprehending industry-specific constraints and tailoring the label accordingly is crucial.

Case studies and examples serve as practical insights, demonstrating the application of regulations and the manifestation of industry-specific label designs, helping in navigating the intricate landscape of industry-specific label printing.

Sustainable Label Printing

The emphasis on sustainability has permeated the domain of label printing, promoting the adoption of eco-friendly materials and processes. Designing labels with a sustainable ethos involves a conscientious approach to material selection and printing methodologies.

It’s about embracing sustainability not just as a trend but as a responsibility, reflecting the brand’s commitment to ecological balance and environmental conservation.

Future Trends in Label Printing

Peering into the future reveals trends like augmented reality and smart labels reshaping the label printing landscape. Staying abreast of emerging technologies and trends is essential to ensure the labels are contemporary and resonate with evolving consumer expectations.

It’s about foreseeing the convergence of technology and design, sculpting labels that are not just visually appealing but are also interactive portals to brand experiences.